For a long time, most of the substrate materials of high-power hybrid integrated circuits have been using Al2O3 and BeO ceramics, but the thermal conductivity of the Al2O3 substrate is low, and the thermal expansion coefficient is not well matched with Si. Although the comprehensive performance of BeO is excellent, its high production cost and highly toxic shortcomings limit its application and promotion. Therefore, from the performance, cost and environmental protection factors, the two can not meet the needs of modern electronic power devices and development.

Aluminum nitride ceramics have excellent comprehensive properties, is a new generation of advanced ceramics that has been widely concerned in recent years, and has a wide range of application prospects in many aspects, especially its advantages of high thermal conductivity, low dielectric constant, low dielectric loss, excellent electrical insulation, thermal expansion coefficient matching silicon and non-toxicity. Making it an ideal material for high-density, high-power and high-speed integrated circuit boards and packages.

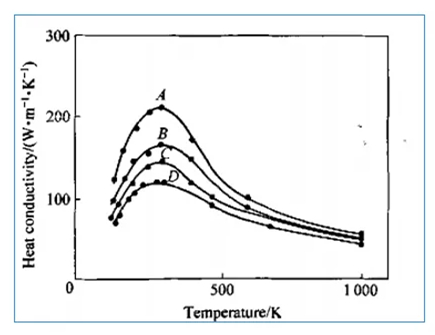

High thermal conductivity is the most significant characteristic of aluminum nitride substrate. The main mechanism is: through lattice or lattice vibration, that is, through lattice wave or thermal wave heat transfer.

AlN ceramics are insulating ceramic materials, for insulating ceramic materials, heat energy is transferred by atomic vibration, which belongs to phonon heat conduction, phonons play an important role in its heat conduction process. The thermal conductivity of aluminum nitride can theoretically reach 320w/ (m·k), what causes this gap?

There are impurities and defects in aluminum nitride, resulting in the thermal conductivity of aluminum nitride substrate is far from the theoretical value. The impurity elements in the aluminum nitride powder are mainly oxygen and carbon, and there are also a small amount of metal ion impurities, which produce various defect forms in the lattice, and the scattering of these defects on the phonon will reduce the thermal conductivity.

So what are the factors that affect the mean free path of phonons?

1. In the heat transfer process, the defects, grain boundaries, holes, electrons and phonons themselves will produce phonon scattering, thereby reducing the mean free path of phonons and further affecting the thermal conductivity.

Impurity oxygen and Al2O3 play a major role in phonon-defect scattering.

1. Because AlN is easy to hydrolysis and oxidation, a layer of Al2O3 is formed on the surface, and Al2O3 is dissolved into the AlN lattice to produce aluminum vacancies. 2.AlN has a strong affinity with oxygen, which is easy to enter the aluminum nitride lattice, and the oxygen in the lattice has a high displacement solubility, which is easy to form oxygen defects.

The relationship between defects in the AlN lattice and oxygen concentration:

When [O] <0.75% O is uniformly distributed in the AlN lattice, it occupies the N position in AlN and is accompanied by Al vacancy.

When [O] ≥0.75% Al atom position changes, Al vacancy is eliminated at the same time, and an octahedral defect is formed.

At higher concentrations, extended defects will be formed, such as oxygen-containing layer faults, inversion domains, polybodies, etc.

The presence of oxygen impurities seriously affects the thermal conductivity of AlN. The presence of oxygen defects increases the scattering area cross section of phonons and decreases the thermal conductivity of AlN.

Therefore, the presence of oxygen impurities seriously affects the thermal conductivity of AlN, which is the main factor for the reduction of thermal conductivity.

In summary, aluminum nitride ceramics with its unique comprehensive properties, especially its high thermal conductivity, low dielectric constant, low dielectric loss, excellent electrical insulation and silicon matching thermal expansion coefficient and non-toxicity characteristics, become the ideal material for modern high-density, high-power and high-speed integrated circuit board and packaging. However, the actual thermal conductivity of aluminum nitride ceramics is often much lower than its theoretical value, which is mainly due to the presence of impurities and defects in the material, especially oxygen impurities, the scattering effect on the phonon heat transfer process.

Oxygen impurities not only easily enter the aluminum nitride lattice to form oxygen defects, but also cause more complex crystal structure changes at higher concentrations, such as octahedral defects, oxygen-containing layer faults, inversion domains, etc., which greatly reduce the thermal conductivity of aluminum nitride. Therefore, optimizing the preparation process of Al nitride ceramics, reducing the content of oxygen impurities and controlling the formation of crystal defects are the key to improve the thermal conductivity of Al nitride ceramics.

Looking forward to the future, with the continuous progress of material science and preparation technology, the performance of aluminum nitride ceramics will be further improved, and its application in high-power integrated circuit board and other high-tech fields will be more extensive and in-depth. At the same time, the in-depth study on the thermal conductivity mechanism and influencing factors of aluminum nitride ceramics will also provide important reference for the development of other advanced ceramic materials.